The 5 Whys Template

The 5 whys template - Basically, you are taking your problem and creating a procedural chart using symbols. It’s the best possible path to success. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Each symbol has its own meaning, such as a statement box or a decision box. 5 whys root cause analysis template. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. The 5 whys analysis was developed by taiichi ohno, the pioneer of the toyota production system in the 1950s. He details his method of problem solving in his book, toyota production system: The beginning of the 5 whys. Each of these ‘boxes’ is then connected with.

Developing the skills for a fabulous career isn’t just a nice idea. The technique ohno developed was so effective that toyota uses it to this day.

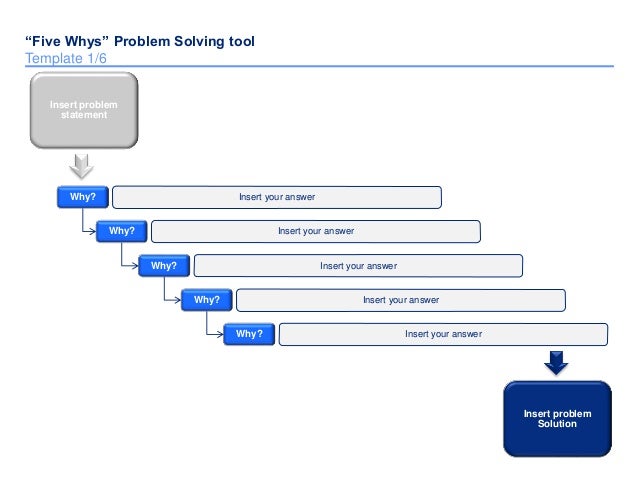

5 Whys Root Cause Analysis Template

Each symbol has its own meaning, such as a statement box or a decision box. Each of these ‘boxes’ is then connected with. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a.

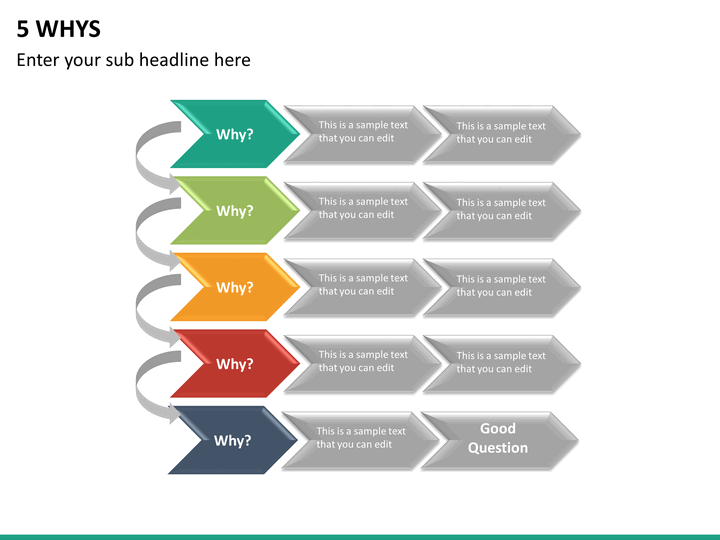

5 Whys PowerPoint Template SketchBubble

Developing the skills for a fabulous career isn’t just a nice idea. The 5 whys analysis was developed by taiichi ohno, the pioneer of the toyota production system in the 1950s. The technique ohno developed was so effective that toyota uses it to this day.

5 Whys PowerPoint Template SketchBubble

Developing the skills for a fabulous career isn’t just a nice idea. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. The technique ohno developed was so effective that toyota uses it to this day.

Download Now a 5 Whys Template By exMcKinsey Consultants

The beginning of the 5 whys. The technique ohno developed was so effective that toyota uses it to this day. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a.

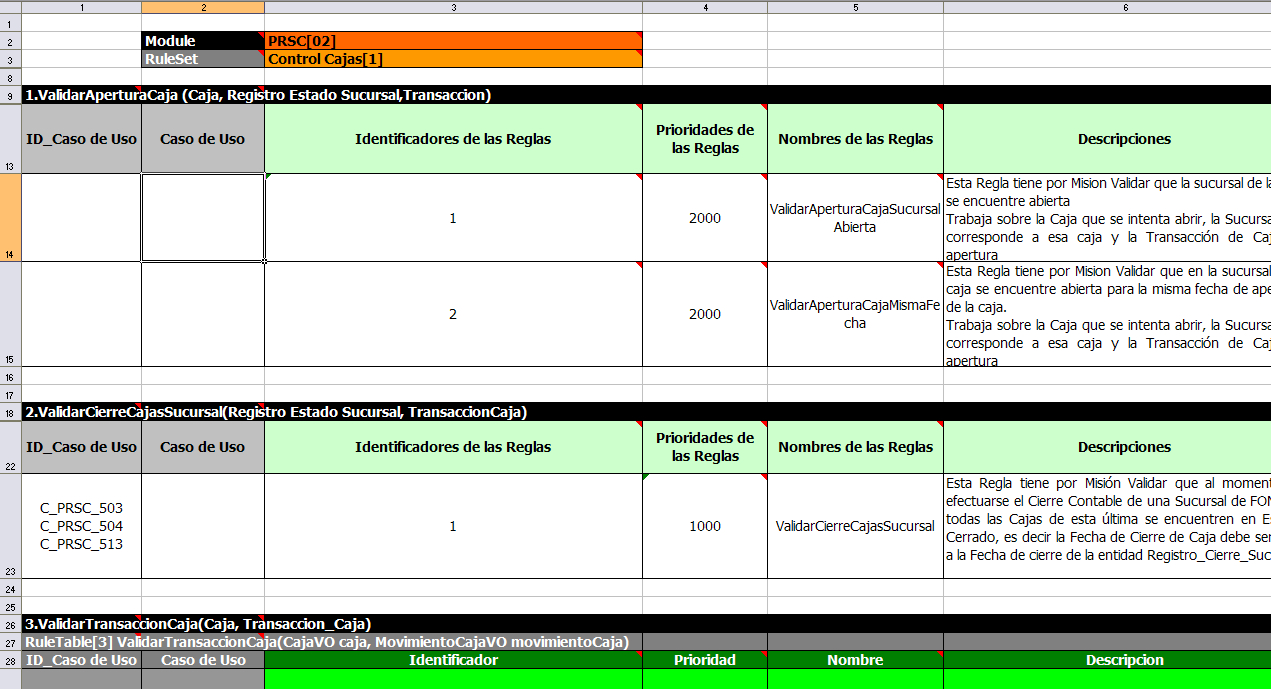

5 Whys Template Excel Xls Spreadsheet In Chapter 6. Authoring 5 Whys

Basically, you are taking your problem and creating a procedural chart using symbols. The technique ohno developed was so effective that toyota uses it to this day. It’s the best possible path to success.

5 Whys how to find the real problems YouTube

Developing the skills for a fabulous career isn’t just a nice idea. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Each of these ‘boxes’ is then connected with.

5 Whys Fishbone Diagram PLUS Other Methods of Root Cause Analysis

It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Each symbol has its own meaning, such as a statement box or a decision box. 5 whys root cause analysis template.

Essential Lean Management Presentation Diagrams PPT template with

This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. The beginning of the 5 whys. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a.

The beginning of the 5 whys. It’s the best possible path to success. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. The 5 whys analysis was developed by taiichi ohno, the pioneer of the toyota production system in the 1950s. The technique ohno developed was so effective that toyota uses it to this day. 5 whys root cause analysis template. Each symbol has its own meaning, such as a statement box or a decision box. Basically, you are taking your problem and creating a procedural chart using symbols. Developing the skills for a fabulous career isn’t just a nice idea. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template.

He details his method of problem solving in his book, toyota production system: Each of these ‘boxes’ is then connected with.